Honestly, if someone had asked this question ten years ago, most people would’ve laughed and moved on. Earthworms? As protein? That sounded more like survival TV than serious nutrition talk.

But things have changed. A lot.

As pressure mounts on traditional protein systems—soy, dairy, fishmeal, even pea protein—buyers across dietary supplements, nutraceutical ingredients, pharmaceuticals ingredient and cosmetics material are asking tougher questions. Not just how much protein a material offers, but where it comes from, what it costs the planet, and whether it still works at scale.

So let’s slow down and look at it clearly: is earthworm protein powder actually a sustainable protein source, or just another headline-grabber?

First, why sustainability suddenly matters so much

Here’s the thing. Protein demand isn’t slowing down. Sports nutrition keeps growing. Functional foods are everywhere. Clinical nutrition and pharma excipients want cleaner, more traceable inputs. Even cosmetics are leaning into bioactive proteins.

Yet traditional sources are showing cracks:

- Dairy protein ties directly to land use, methane emissions, and water strain

- Soy protein still raises deforestation and monoculture concerns

- Marine proteins face overfishing and supply instability

You know what that leads to—price volatility, regulatory pressure, and uncomfortable conversations with procurement teams.

That’s why alternative proteins aren’t just trendy anymore. They’re practical.

What exactly is earthworm protein powder?

Let me explain it simply, without the hype.

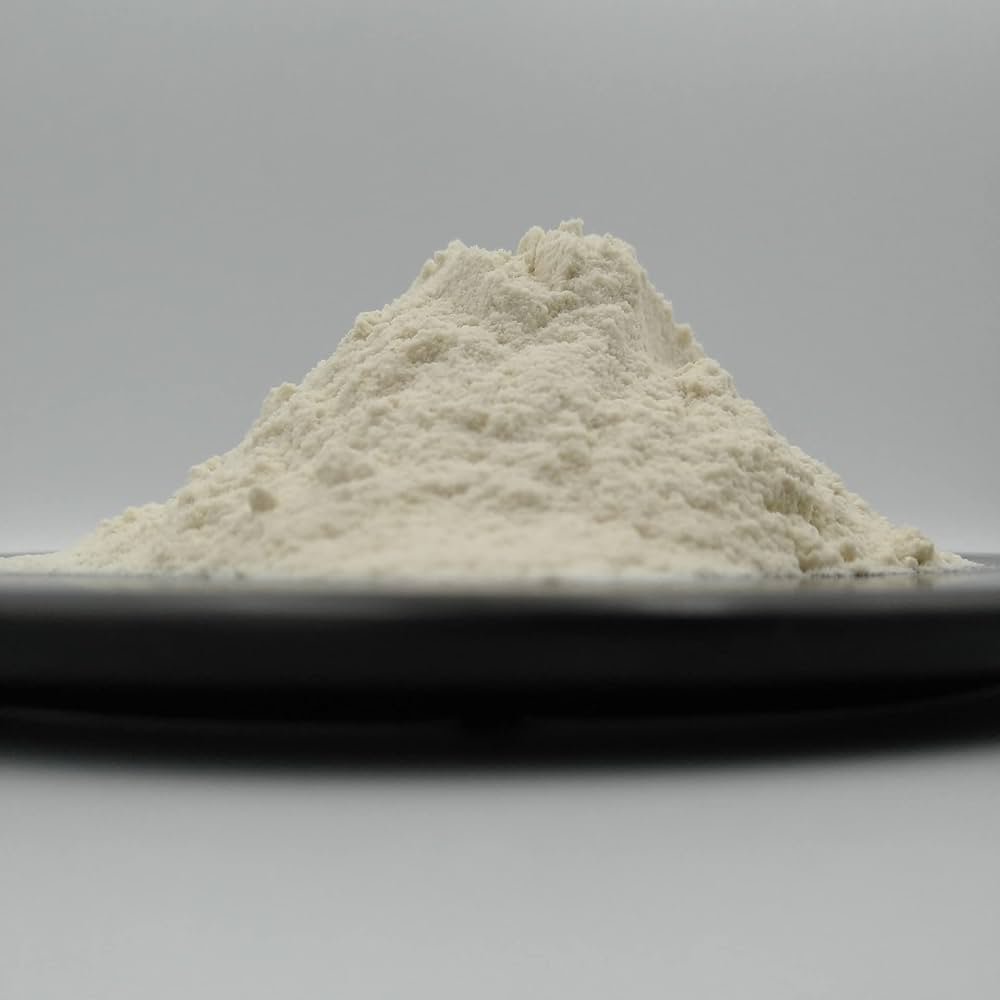

Earthworm protein powder is produced from cultivated earthworms, processed through controlled extraction, purification, and drying. The result is a high-protein material, rich in essential amino acids, peptides, and functional bioactives.

In industrial terms, it sits somewhere between:

- a complete protein ingredient, and

- a biofunctional raw material (especially relevant for nutraceutical and pharma use)

And no, this isn’t backyard compost harvesting. Commercial production relies on standardized vermiculture systems, often integrated with agricultural waste recycling.

That detail matters a lot when we talk sustainability.

Sustainability starts at the farm level

Earthworms are, frankly, low-maintenance overachievers.

Compared to livestock or even plant protein crops:

- They require very little land

- They consume organic byproducts (agricultural waste, food waste)

- They reproduce quickly and efficiently

- They don’t need antibiotics, pesticides, or fertilizers

You know what that means in practice? A shorter, tighter production loop.

Instead of clearing land or irrigating crops, earthworm farming often reduces waste streams. That’s already a win before processing even begins.

Carbon footprint: surprisingly modest

When sustainability teams run life-cycle assessments, protein sources don’t all look equal.

Earthworm protein production typically shows:

- Lower greenhouse gas emissions than dairy and beef proteins

- Minimal methane output

- Reduced energy input compared to some plant protein isolations

Processing still uses energy—drying always does—but overall, the carbon profile remains comparatively light, especially when operations are localized.

For B2B buyers under ESG pressure, that’s not a small detail. It’s a checkbox that suddenly becomes a selling point.

Water use: an underrated advantage

Water scarcity rarely makes headlines in protein marketing, but it keeps supply chain managers awake at night.

Earthworm cultivation requires significantly less water than soy or dairy protein production. No irrigation cycles. No massive cleaning loops. No water-intensive feed crops.

In regions like Southeast Asia, the Middle East, and parts of Europe, that alone makes earthworm protein powder a strategic option rather than a novelty.

Nutritional density: sustainability meets functionality

Sustainability doesn’t mean much if the protein doesn’t perform.

Here’s where earthworm protein quietly surprises people.

It typically offers:

- High crude protein content

- A balanced essential amino acid profile

- Naturally occurring peptides with functional properties

That’s why you see interest not only from supplement brands, but also from pharmaceutical ingredient developers and cosmetic formulators.

A protein that does more with less raw material? That’s efficient by definition.

But what about scalability?

Fair question. And this is where early skepticism was justified.

Small-scale worm farming doesn’t impress global buyers. However, industrial vermiculture has matured. Controlled environments, automated feeding, and standardized extraction now allow for consistent, repeatable output.

Is it as large as whey protein supply chains? Not yet.

Is it scalable enough for regional B2B demand, contract manufacturing, and ingredient supply? Increasingly, yes.

Especially when production is vertically integrated—from cultivation to extraction—supply stability improves fast.

Regulatory and quality considerations

Here’s the part professionals care about.

Earthworm protein powder intended for dietary supplements, nutraceuticals, pharma intermediates, or cosmetic raw materials must comply with:

- Microbiological standards

- Heavy metal limits

- Traceability and batch consistency

- Clear documentation on origin and processing

When sourced from experienced manufacturers, these boxes can be checked. When sourced casually, they can’t.

That’s why most serious buyers work directly with specialized producers, not brokers who treat it like a commodity powder.

Cultural acceptance: the quiet shift

Let’s be real—consumer-facing branding still has hurdles. Earthworms don’t scream “delicious.”

But sustainability conversations are changing perception. Consumers already accept:

- collagen from hides

- enzymes from fermentation

- peptides from marine byproducts

For B2B applications where the ingredient isn’t front-and-center, acceptance becomes less emotional and more practical.

And honestly? In capsules, powders, creams, or tablets, origin matters less than efficacy and footprint.

How earthworm protein fits into the bigger protein mix

Here’s a mild contradiction worth addressing: earthworm protein probably won’t replace soy or whey entirely.

And that’s okay.

Sustainability rarely comes from one silver bullet. It comes from diversification.

Earthworm protein powder works best when it:

- reduces dependence on stressed protein sources

- supports specialized formulations

- strengthens regional supply chains

- adds functional value beyond nutrition

Seen this way, it’s not competing—it’s complementing.

So… is it actually sustainable?

If sustainability means:

- lower environmental impact

- efficient use of resources

- waste reduction

- functional output per unit input

Then yes—earthworm protein powder makes a strong case.

It’s not hype. It’s not perfect. But it fits where modern protein systems need help most.

And for manufacturers, formulators, and ingredient buyers thinking five or ten years ahead, that matters more than novelty.

Frequently Asked Questions

Is earthworm protein powder environmentally friendly compared to traditional proteins?

Yes. Earthworm protein powder generally uses less land and water and produces fewer emissions than dairy or livestock proteins, making it an environmentally friendly alternative protein source.

Can earthworm protein powder be used in dietary supplements and nutraceuticals?

Absolutely. Its high protein content and bioactive peptides make earthworm protein powder suitable for dietary supplements, nutraceutical ingredients, and functional formulations.

Is earthworm protein powder safe for pharmaceutical or cosmetic applications?

When produced under controlled conditions with proper quality standards, earthworm protein powder can meet pharmaceutical and cosmetic ingredient requirements.

How scalable is earthworm protein powder production?

Modern vermiculture systems allow scalable production suitable for B2B supply, especially when vertically integrated from farming to extraction.

Does earthworm protein powder have a neutral taste or odor?

Refined earthworm protein powder is typically processed to reduce strong odors or flavors, making it adaptable for capsules, tablets, and blended formulations.